charpy impact test brittle area|charpy impact test calculation table : fabrication Brittle steel does not deform very much during failure and requires less than 15 ft-lbs energy to cause failure. Characterizing the toughness of a material is done in several ways. The most . WEBCentro de Previsão de Tempo e Estudos Climáticos. Portais . Tempo Clima Previsão Numérica Satélite Ondas Dados Observacionais Instrumentação Bacias Qualidade do Ar Pós Graduação. Sobre . Sobre o CPTEC Perguntas Frequentes Ouvidoria Links Indicados Biblioteca. Produtos .

{plog:ftitle_list}

Sigaa - UFERSA - SIGAA

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its .

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .Brittle steel does not deform very much during failure and requires less than 15 ft-lbs energy to cause failure. Characterizing the toughness of a material is done in several ways. The most .This change is called a ductile to brittle transition (DTBT). The CIT provides a and reliable method to measure the relative change in rapid impact toughness of a material as it becomes .

In a Charpy impact test, three key measurements are typically made: total absorbed energy, lateral expansion, and percent shear fracture area.In the Charpy impact test, an impact load is applied to a test piece using a pendulum hammer in order to fracture it. The impact value is derived from the energy at the time the test piece fractured, and is used to evaluate the . This inexpensive and simple test is applicable to determine a material’s brittleness—higher energy indicates ductility, while lower energy suggests brittleness.In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .

The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value. Metals with high impact strength . The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized .Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step .

The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. Charpy impact testing determines the impact energy of materials.Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value.Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. . Influence of impact energy with the damage area in brittle composite laminates (reproduced from [53]). 3.1.4 .

In the charpy impact test we use a test specimen which have a notch at one side of it. Figure 4 — Specimen Deformation of the material is confined to a small volume and stress in concentrated .

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .Test results, especially in Europe, may be reported as energy lost per unit cross-sectional area (J/m 2 or ft-lb/in 2). What are the test methods to measure toughness? Test methods used to measure Notched Izod Impact (or notch sensitivity) and Charpy Impact in plastics are: ASTM D256-10(2018): Plastics — Determination of Izod pendulum impact .to provide a stress concentration area that promotes a brittle rather than a ductile failure. A plastic deformation is also prevented by such type of notch in the specimen. The impact values are seriously affected because of the . Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss

charpy impact testing procedure

In a Charpy impact test, three key measurements are typically made: total absorbed energy, lateral expansion, and percent shear fracture area. At present, the measurements of absorbed energy and lateral expansion are quantitative and well defined, but the methods used by most laboratories in the measurement of percent shear are qualitative at best.to provide a stress concentration area that promotes a brittle rather than a ductile failure. A plastic deformation is also prevented by such type of notch in the specimen. The impact values are seriously affected because of the . Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss

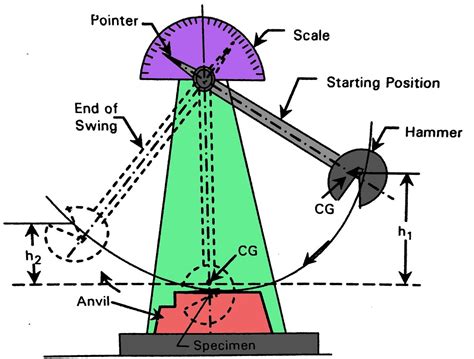

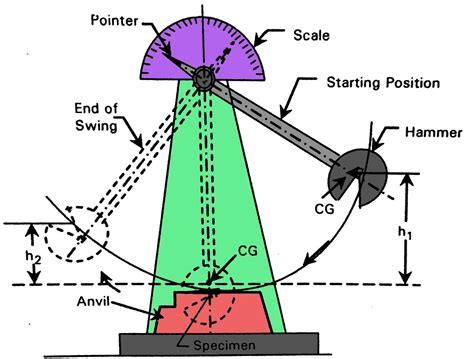

Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with -centered-cubic (bcc) crystalline body materials. These materials show a transition from ductile to brittle behavior with temperature (Figure 2-2). This means that at low temperature the fracture energy is low.

Charpy Test. In subject area: Engineering. . it can be confidently assumed that the material is unlikely to experience problems with brittle fracture. If, however, a Charpy test result is slightly less than the specified minimum value of 40 . Modeling the Charpy impact test is a challenging issue, since several aspects of this test require . ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens. Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.to provide a stress concentration area that promotes a brittle rather than a ductile failure. A plastic deformation is also prevented by such type of notch in the specimen. The impact values are seriously affected because of the . Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss

The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen .Many specifications talk of a transition temperature, a temperature at which the fracture behaviour changes from ductile to brittle.This temperature is often determined by selecting, quite arbitrarily, the temperature at which the metal . Charpy and Izod tests are conducted to determine the impact energy of different materials. Ductile to brittle transition can be found by testing charpy speci.

2009. The aim of this study was evaluated the ductile-to-brittle transition temperature (DBTT) by five different methods: lateral expansion, shear fracture appearance, the average between lower and upper-shelf, load diagram and master curve using instrumented Charpy tests with total impact energy was 300 J and the impact velocity was 5.12 m/s.Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to . This change is called a ductile to brittle transition (DTBT). . sectional area of the compact samples in the current work is approximately 10 times smaller than full-sized samples, so the amount of energy absorbed would be . Therefore, grain refinement significantly improves the ductile-to-brittle transition temperature (DBTT) obtained in the Charpy impact test, Izod impact test, and single-edge notched bending test, as shown in Figure 1 [12,13,14,15]. The improvement of σ F as well as σ ys is one of the advantages of grain refinement. This work presents the Charpy energy values (CVN) in the ductile-to-brittle transition (DBT) temperature zone for different directions with respect to the longitudinal direction of API 5L X52 seamless pipeline steel. The material-processing directions were L-T, T-L, S-T, T-S, L-S, S-L, and 45°. At the same time, the temperature variation was –100, 0, 25, 50, and .

What is the charpy impact test – The charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material’s notch toughness. The objective of the charpy impact test ?? To determine the material resistance to impact from a .

charpy impact testing methods

paint lab test

Shear fracture percentage is, therefore, a parameter used to quantify the amount of ductile shear fracture a material experiences at the fracture surface. The shear fracture percentage area is one of the key measurements made during a Charpy impact test.

Standard E 23, ―Standard Test Methods for Notched Bar Impact Testing of Metallic Materials‖. In 1901, a French researcher named Charpy published his work—the second publication in the world on pendulum machine testing—on notched bar pendulum impact tests [2]. Charpy’sto provide a stress concentration area that promotes a brittle rather than a ductile failure. A plastic deformation is also prevented by such type of notch in the specimen. The impact values are seriously affected because of the . Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, tossto provide a stress concentration area that promotes a brittle rather than a ductile failure. A plastic deformation is also prevented by such type of notch in the specimen. The impact values are seriously affected because of the . Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss

test paint lowes

charpy impact test sample

o estudante matriculado em Instituições de Ensino situadas no município de Araraquara e sua microrregião obtém o beneficio de andar de ônibus com a redução de tarifa de 50%. Saiba Mais . Pontos de Recarga: Terminal .

charpy impact test brittle area|charpy impact test calculation table